Recycling magic

Plastics recycling is an extremely sensitive subject worldwide. Are you R keeps on tackling this issue not only to raise consumer awareness, but also to show less-known technical aspects of its process, in addition to raise awareness of a material that is commonly demonised, simply because, actually, little is known about it. If it’s undeniable that plastic has become a major player in climate struggles – let’s face it, it’s a potentially harmful and polluting material, if we don’t manage it correctly – it’s also undeniable that, through the years, thanks to its numerous qualities, it has become immensely important in various areas.

Therefore, at a point in history when news is within reach – and sometimes unreliable, though -, Are you R would like to offer you an objective point of view and correct information about this topic. How? By letting professionals talk about everything that might be invisible to the eye, by allowing every day room for an active and conscious debate, which is created by a community of tens of thousands of users.

How does plastics recycling really work? Find it out here!

1.

VIRGIN PLASTIC

The most used and produced, in addition to being the target of current climate struggles. It’s a polymeric material, that is composed of long-chain molecules, whose chain determines their features. Plastic has ancient origins: rayon, that is the artificial fibre which preceded it, was created for the first time in 1855. Just like we told you in this article, there are many plastic materials and all different from each other. It is essential to know about them in order to become well-informed consumers and, most importantly, to contribute to their recycling!

2.

USE

Depending on the type, plastic materials have been used for an almost infinite variety of purposes since the beginning. In addition to the commonly used products, there are also some plastics, which are more suitable for industrial production processes, for they have a particular mechanical strength; other ones are even suitable for creating infrastructures and building components; not to mention their use in the field of personal safety (take, for example, cars and helmets components) and in the medical sector, that is a sensitive and important field. Plastic materials can really be used for countless purposes and, right for this reason, they’re hardly replaceable. That’s why plastics recycling plays a crucial role!

3.

COLLECTING AND SORTING

Our contribution as consumers is precious if we separate plastic waste correctly. An effective recycling often begins at home! After its collection, plastic waste undergoes a sorting process, that is a fundamental step of the recycling process. Indeed, depending on the type of material, plastic waste undergoes a certain recycling procedure. At this stage, the optical selection is a crucial instrument.

4.

CLEANING AND DECONTAMINATING

So, yes, plastic waste also needs to be washed and cleaned before being admitted to the next recycling stage. For instance, plastic bottles (PET) are washed in warm water in order to remove any label residue or different types of dirt, in addition to undergoing specific processes aimed at removing further unsuitable materials. Only after plastic has been cleaned, it can indeed be recycled.

5.

GRINDING

When it comes to chemical characteristics and applications, plastic materials differ greatly from one another. They have one thing in common, though: they all need to be dimensionally reduced through a grinding process, which is a crucial step to ensure the quality of the final product. By grinding it, it’s possible to obtain a flake that, after being compressed into recycled plastic pellets ready for regeneration, makes it possible to fully recover plastic waste.

6.

EXTRUSION

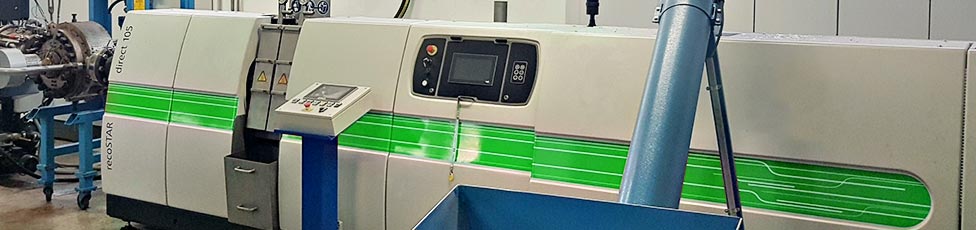

It’s crucial to obtain pellets. During the extrusion process, three different machines are used to achieve a high-quality final result.

The extruder has a primary function to melt the plastic material by using a heated turning screw. Moreover, it removes the gaseous components that can be found in the material itself, which had been generated by inks and contaminants.

7.

FILTRATION

It’s a crucial step that concerns the final quality of the recycled plastics, so that they can be re-used effectively.

Plastic may indeed contain a small percentage of impurities, such as paper – in the case of labels-, but also wood, aluminium, rubber, not-melted plastics, etc.

In order to re-use recycled plastic, right after its fusion, it will be necessary to filter it by using an extruder. The melted plastic material is filtered by using a specific machine, which removes everything that does not match the processed material.

8.

GRANULATION

Granulation is the result of all previous steps of the recycling process. The stage, which allows us to obtain recycled plastic pellets, is easy, but requires certain conditions. Basically, melted plastic comes out of specific holes, in the form of real ‘spaghetti’, which are subsequently cut with appropriate knifes. That way, depending on the diameter of the holes and the rotational speed of the blades, it’s possible to obtain pellets with variable diameter and length, also according to the different needs of the finished product that must be obtained. Now we just have to create new ready-to-use recycled plastic products!